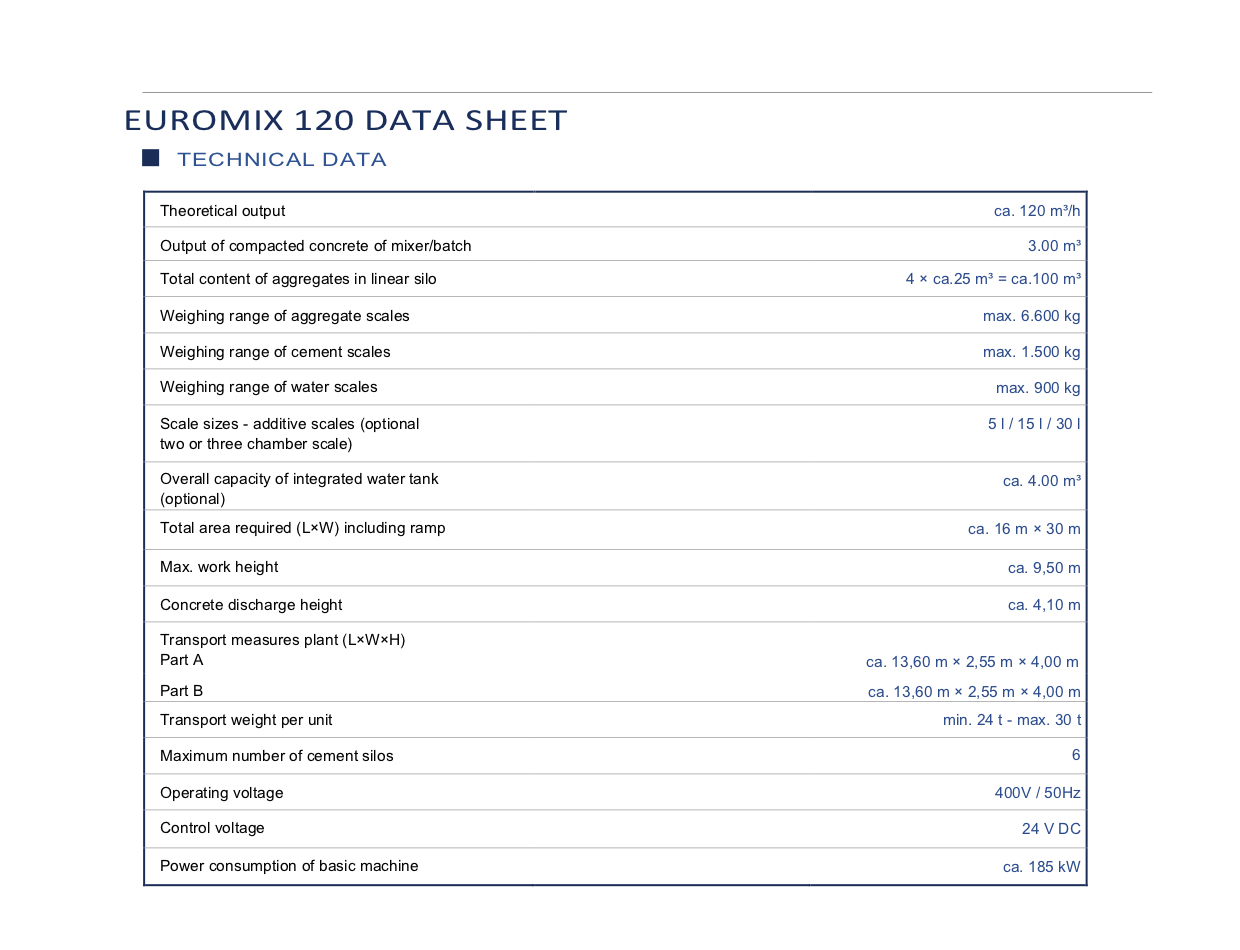

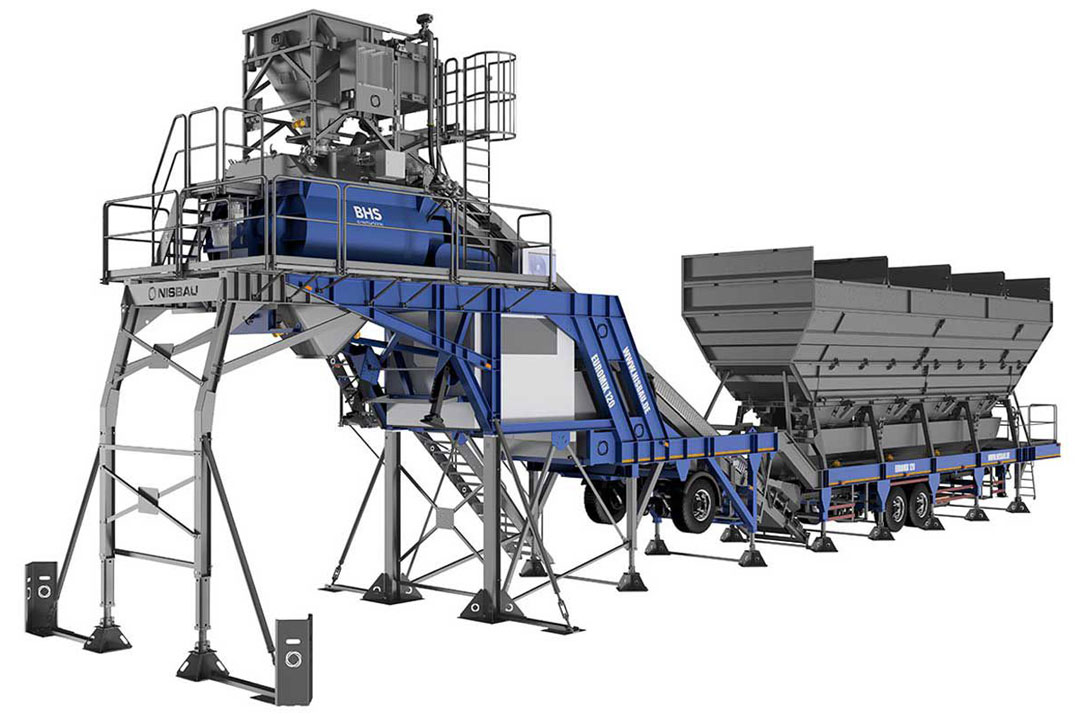

NISBAU [EUROMIX] 120

High Capacity, Mobile Concrete Batching Plant

Class Leading Capability – Made in Germany

OUTPUT 120 m³/h

Mixer 3.0 m³

[EUROMIX] 120

REVISED DESIGN – CONTINUOUS DEVELOPMENT – HIGH MOBILITY

With the [EUROMIX] 120 series, we provide our clients with timely and efficient production of quality concrete, even in difficult areas such as traffic junctions, city centres and ports. Aspects such as the compact construction for road transport, plug-in connections, factory-tested, installed and matched components allow ASSEMBLY within a day. To enable independent operation of the systems, they can be optionally equipped with a generator set. On an area of only 400 m², the entire concrete plant can be realized.

(Installation area including silos and ramp)

FOUNDATION-FREE INSTALLATION

for the complete system

TWO TRANSPORT UNITS

ROBUST DESIGN AND EASY ASSEMBLY CONSTRUCTION

400 m2 area

INCLINED CONVEYOR BELT

Feeding direct to the mixer/hopper

INDIVIDUALLY ADAPTABLE

Cleaning systems, video cameras, drive units, funnel options, wear liners, silo systems, recycling plant

[EUROMIX] 120

the most reliable, efficient & proven ready mix concrete batching plant, standing out above all for fully mobile Features

MADE IN GERMANY

WORLDWIDE USE

Concepts & Changes

Based on the EUROMIX 100, various sections have been revised with the aim of maximising the output. The modifications include the deployment of a new mixing plant as well as increasing the size of the row-type silo for aggregates. All weighing systems and conveyor belt systems have been adapted to the new batch size. The focus during development was clearly on increasing the output with the same level of ease in handling. Thanks to the plug & play principle, the system is installed or dis-mantled in only 8 hours.

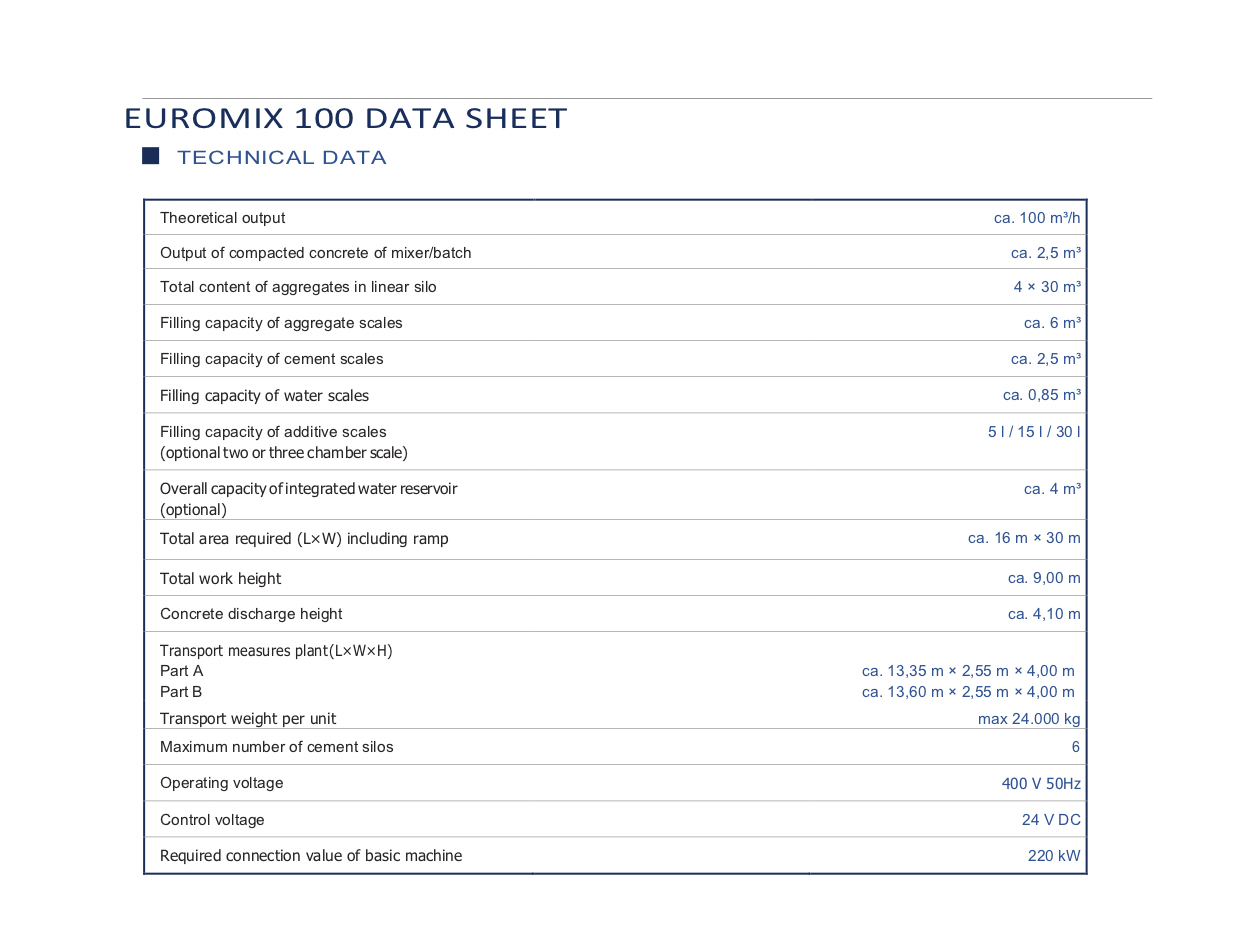

NISBAU [EUROMIX] 100

RELIABLE, EFFICIENT Mobile Concrete Batching Plant

Class Leading Capability – Made in Germany

OUTPUT 100 m³/h

Mixer 2.5 m³

[EUROMIX] 100 – THE BEST IN CLASS

HIGH PERFORMANCE CONCRETE BATCHING PLANT

With the [EUROMIX] 100 series can produce quality concrete prompts and efficiently even at difficult locations such as traffic junctions, city centres and ports.Various aspects such as modular construction, plug-in connections, and components installed and matched at the factory enable the system to be set up in only two days. In order to be independent from external power supply the mixer system can also be provided with an optional generator.

With a width of only 2.55 m and a maximum weight of 29 tons (per unit), we ensure quick implementation that does not need any approvals for heavy or special transport. Overall, this series is divided in 2 transport units that are drawn by two conventional tractors.

Features & Design

Highly robust and durable mixer system, in addition to an integrated 5000 l water tank, a weighing system that can be calibrated and a control system certified by PTB make the entire package complete. The system is almost completely galvanised (Optional) in order to prevent corrosion. This ensures conservation of value even after several years of use. When using various components, only renowned quality products have been selected that meet the requirements and standards.

OPTIONS

BHS PERFORMANCE MIXERS

BHS DKX Twin-Shaft Batch Mixer

Twin-Shaft mixing technology is suitable for all formulas and offers a wide range of benefits. The mixing technique has a significant effect on the quality of the mixture and the economic efficiency of the production process.Furthermore, mixing results are consistent and reliable, and this is thanks to the proven design and arrangement of the mixing tools, consistent homogenous mixtures batch after batch in less time is achieved by this. Maintenance-friendly and Robust design;

CAPACITY

MADE IN GERMANY

MIXING CONCEPT

GEN 3D

Generation 3D, circular three-dimensional pattern for rapid mixture of batch ingredients

TURBULENT OVERLAP AREA

Intensive material exchange in the turbulent overlap area of the two mixing circles

ENERGY CONVERSION

Optimal conversion fo the input energy into intensive relative movements of the mixtures

FREE FLOW MOVEMENT

Rapid movement of all the materials throughout the mixer during the entire mixing process

The Benchmark in mixing technology

Rapidly producing mixures with consistently high levels of homogenity.

EFFICIENCY

Rapid, optimal suspension of cementitious materials

CEMENT CONTENT REMOVAL

GUARANTEED UNIFORM AND FAST DISTRIBUTION

of admixtures and additives throughout the mixture

OPTION FOR SMALL BATCHES

From 10% of nominal filling level, creating the perfect size batch

FUTURE-PROOF

Design allows for modern concrete formulas

Nisbau Egypt

7 Zaki Rostom St. Nasr City

Cairo, Egypt

Telephone: +20 222 738 160

Fax: +20 222 738 161

NISBAU [ONE]

[EUROMIX] 120/100

[EUROMIX] 120/100 SM

NISBAU [NOMAS]

EQUIPMENT

Contact us

Social Media