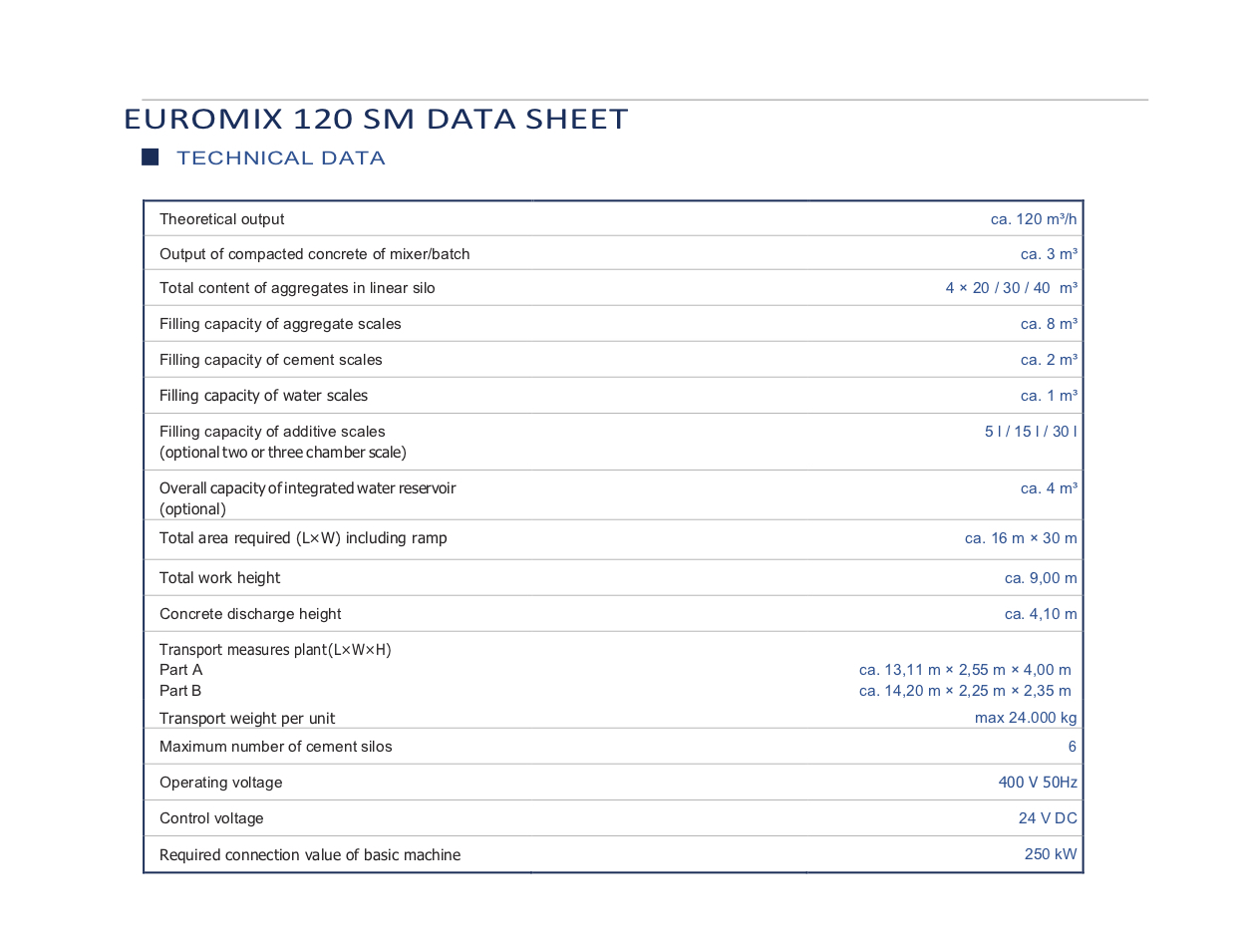

NISBAU [EUROMIX] 120 SM

Stationary Storage, Mobile Mixing Tower

Semi-Mobile Batching plant

OUTPUT 120 m³/h

MIXER SIZE 3.0 m³

[EUROMIX] 120/100 SM

REVISED DESIGN – CONTINUOUS DEVELOPMENT – HIGH MOBILITY

Concepts & Changes

Unlike the [EUROMIX] 120, the Semi Mobile (SM) version has a rear construction for aggregate storage which is stationary. By splitting each chamber, up to 8 different materials can be stored and dosed, which is an advantage compared to the normal 4. Furthermore a storage capacity of 160 m³ can be achieved, by implementing a feeding conveyor belt ramp constructions are completely unnecessary. Furthermore, the option to feed the aggregate bins via truck dumper can be realised. The front part, which contains the mixer, water, cement, and additive scales as well as the control cabin is identical to the full mobile version. The [EUROMIX] 120 SM fulfils all the quality features of a modern plant, ease of handling, reliability and robustness, as well as the ability to modernise (Shift the system to a completely mobile system) should you need it.

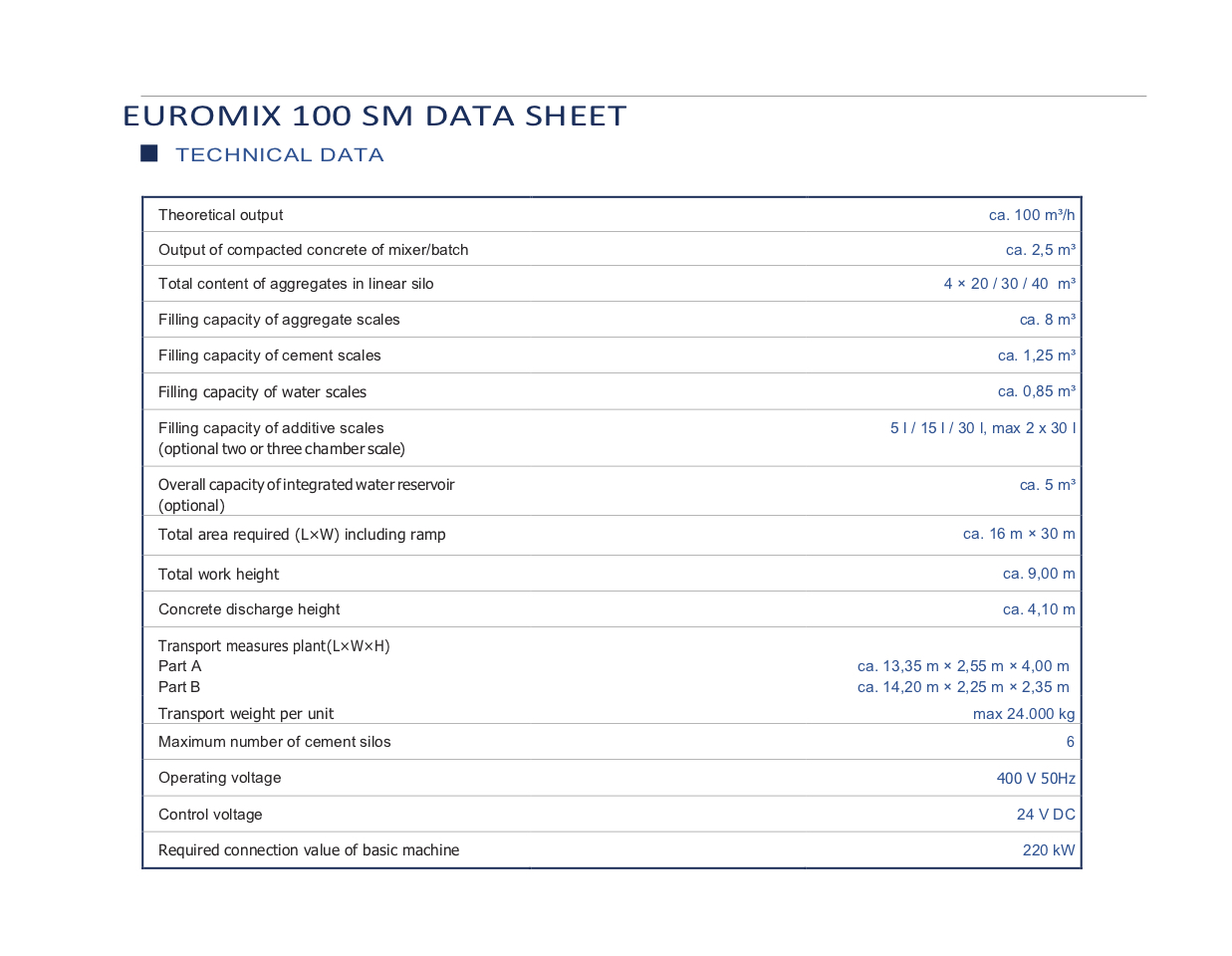

NISBAU [EUROMIX] 100 SM

SEMI MOBILE CONCRETE BATCHING PLANT

OUTPUT 100 m³/h

MIXER 2.5 m³

The first part with the chassis is equivalent to the [EUROMIX] 100, there are no differences in terms of power, handling and installation. The rear part is a linear silo design for aggregates. This part is not installed on a chassis, however on a rack. The construction can be transported on a trailer however when realising the plant a crane must be used. Furthermore the size of the aggregate storage increases up to 40 m³. In comparison, the [EUROMIX] 100 provides a maximum capacity of 22 m³ per storage unit. All dosing options and weighing systems that can be calibrated are ensured.With less frequent relocation changes, this mixer system is the right choice, since this version retains its mobile feature despite stationary or fixed elements.

OPTIONS

BHS PERFORMANCE MIXERS

BHS DKX Twin-Shaft Batch Mixer

Twin-Shaft mixing technology is suitable for all formulas and offers a wide range of benefits. The mixing technique has a significant effect on the quality of the mixture and the economic efficiency of the production process.Furthermore, mixing results are consistent and reliable, and this is thanks to the proven design and arrangement of the mixing tools, consistent homogenous mixtures batch after batch in less time is achieved by this. Maintenance-friendly and Robust design;

CAPACITY

MADE IN GERMANY

MIXING CONCEPT

GEN 3D

Generation 3D, circular three-dimensional pattern for rapid mixture of batch ingredients

TURBULENT OVERLAP AREA

Intensive material exchange in the turbulent overlap area of the two mixing circles

ENERGY CONVERSION

Optimal conversion fo the input energy into intensive relative movements of the mixtures

FREE FLOW MOVEMENT

Rapid movement of all the materials throughout the mixer during the entire mixing process

The Benchmark in mixing technology

Rapidly producing mixures with consistently high levels of homogenity.

EFFICIENCY

Rapid, optimal suspension of cementitious materials

CEMENT CONTENT REMOVAL

GUARANTEED UNIFORM AND FAST DISTRIBUTION

of admixtures and additives throughout the mixture

OPTION FOR SMALL BATCHES

From 10% of nominal filling level, creating the perfect size batch

FUTURE-PROOF

Design allows for modern concrete formulas

Nisbau Egypt

7 Zaki Rostom St. Nasr City

Cairo, Egypt

Telephone: +20 222 738 160

Fax: +20 222 738 161

NISBAU [ONE]

[EUROMIX] 120/100

[EUROMIX] 120/100 SM

NISBAU [NOMAS]

EQUIPMENT

Contact us

Social Media