NISBAU [ONE]🇪🇬

FULLY CUSTOMISABLE CONCRETE BATCHING PLANT

CLASS LEADING CAPABILITY

MADE IN EGYPT

VARIABLE OUTPUT UP TO 160 M³/H

MIXER 2.0 – 4.0 M³

NISBAU [ONE]🇪🇬

FULLY CUSTOMISABLE CONCRETE BATCHING PLANT

CLASS LEADING CAPABILITY

MADE IN EGYPT

VARIABLE OUTPUT UP TO 160 M³/H

MIXER 2.0 – 4.0 M³

NISBAU [ONE]

THE NEXT GENERATION OF READY MIX Concrete Batching plants

German Quality – Manufactured in Egypt

STATIONARY, SEMI-MOBILE & MOBILE CONCRETE BATCHING PLANT

ALL IN CUSTOMISABLE

AUTO RUNTIME CORRECTION

Plug and Play modulare design

Fully flexible

Stationary, Semi-Mobile, & Fully Mobile

REMOTE MAINTENANCE

NISBAU [ONE]

THE NEXT GENERATION OF READY MIX Concrete Batching plants

German Quality – Manufactured in Egypt

STATIONARY, SEMI-MOBILE & MOBILE CONCRETE BATCHING PLANT

ALL IN CUSTOMISABLE

Fully flexible

Stationary, Semi-Mobile, & Fully Mobile

REMOTE MAINTENANCE

Plug and Play modulare design

MOST ADVANCED AUTOMATION

RELIABILITY AND AFTER-SALES SERVICE

QUICK INSTALLATION AND ASSEMBLY

8 HOUR REALISATION TIME

VARIABLE OPTIONS

INDVIDUALLY ADAPTABLE

REDIFINING MOBILITY

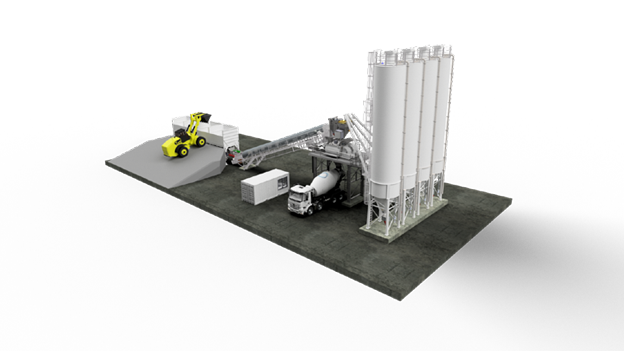

Nisbau [ONE] is the end result of years of experience, and developments in the concrete batching plant field which resulted in a reliable long term concrete producing machine, which can be relocated freely. Nisbau [ONE] can accommodate different capacities, this offers a wide variety of flexibility and mobility. Starting with a minimum output of 100 m3 .Nisbau [ONE] is the next level of Ready Mix Mobile Batching Plants, designed specifically to withstand extreme working conditions whilst maintaining the highest level of quality, mobility and flexibility. We offer high quality concrete while minimising the time and maximising efficiency without comprise in quality. Nisbau ONE offers a fully mobile plant which requires minimised civil engineering costs, just a flat ground and 8 hours for a plant to be realised, interim this saves our clients several hours and provides the solution of combining flexibility and long term reliability for a mobile concrete batching plant, able to be relocated many times per year.

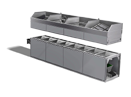

WEIGHING SCALES

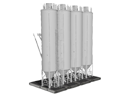

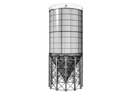

SILOS

ADMIXTURE FEEDING (Per scale)

The Nisbau [ONE] Mobile Plant maintains the class leading design for concrete batching plants, this is due to the intensive research and development, in addition to realising up to 30 concrete batching plants within Egypt and giving clients the flexibility to move sites easily after a project is finished. The Nisbau [ONE] is a fully mobile plant which has all of the advantages of a stationary plant, simultaneously while reducing the cost of construction, manpower and time without comprising in flexibility ,quality and reliability. The integration of our components is what sets our company apart, operating with optional twin, and single shaft BHS mixers, silos with mobile foundations, and accurate aggregate scales. The Nisbau [ONE] is a product of several years of expertise combined with the know how which resulted in technological advancements to the way we utilise Ready Mix Concrete batching plants.

FLEXIBILITY AND MOBILITY

ACCURACY & RELIABILITY

GERMAN DESIGN

NISBAU [one] performance 4.0

FULLY MOBILE AND FOUNDATION-FREE

HIGH PERFORMANCE PLANT – 160CBM / H

DESIGNED IN GERMANY, FOR EGYPT

NISBAU [ONE] PERFOMANCE

INNOVATIVE SUSTAINABLE DESIGNS TAILORED TO CUSTOMER REQUIREMENTS

Lower costs, greater flexibility and faster implementation: Compared with the classic, centralized system solution, modular, decentralized modular systems offer clear economic and technical advantages. As part of our years of experience in plant construction and the versatile needs and requirements of our customers in the field of ready-mixed concrete, large projects, road, tunnel and airport construction, our engineers have developed an independent modular system that leaves nothing to be desired. Our modern technologies such as mixing, storage and conveyor technology are housed in modules that can be combined according to your needs. The completely factory-made modules must then only be connected on site. For inquiries our sales department is at your disposal.

A high-performance system is defined by its output, its operational reliability and its quick and economic feasibility. The model series [ONE] offers a project-oriented system that is still adaptable even after assembly and use. With the optional integrated hopper, after the second batch, this unit achieves discharge levels that are equivalent to a tower plant. Thanks to mobile foundations, the plant can be set up at the desired production site without local foundation work.

VERTIABLE A/D CONVERTERS

For static and dynamic weighing applications

TRACEABLE ACCESS CODE

The system has provided a guard against unauthorized access of the calibration commands

Load Cell Digitising Units (LDU)

7 Point linearisation

SYNCRONISED WEIGHING MODULES

mV/V Calibration

High resolution

Flexibility

Providng optional stationary, semi mobile, and mobile versions for both parts – Aggreggate storage and Mixing Tower

OPTIONS

BHS PERFORMANCE MIXERS

BHS DKX Twin-Shaft Batch Mixer

Twin-Shaft mixing technology is suitable for all formulas and offers a wide range of benefits. The mixing technique has a significant effect on the quality of the mixture and the economic efficiency of the production process.Furthermore, mixing results are consistent and reliable, and this is thanks to the proven design and arrangement of the mixing tools, consistent homogenous mixtures batch after batch in less time is achieved by this. Maintenance-friendly and Robust design;

CAPACITY

MADE IN GERMANY

MIXING CONCEPT

GEN 3D

Generation 3D, circular three-dimensional pattern for rapid mixture of batch ingredients

TURBULENT OVERLAP AREA

Intensive material exchange in the turbulent overlap area of the two mixing circles

ENERGY CONVERSION

Optimal conversion fo the input energy into intensive relative movements of the mixtures

FREE FLOW MOVEMENT

Rapid movement of all the materials throughout the mixer during the entire mixing process

The Benchmark in mixing technology

Rapidly producing mixures with consistently high levels of homogenity.

EFFICIENCY

Rapid, optimal suspension of cementitious materials

CEMENT CONTENT REMOVAL

GUARANTEED UNIFORM AND FAST DISTRIBUTION

of admixtures and additives throughout the mixture

OPTION FOR SMALL BATCHES

From 10% of nominal filling level, creating the perfect size batch

FUTURE-PROOF

Design allows for modern concrete formulas

Nisbau Egypt

7 Zaki Rostom St. Nasr City

Cairo, Egypt

Telephone: +20 222 738 160

Fax: +20 222 738 161

NISBAU [ONE]

[EUROMIX] 120/100

[EUROMIX] 120/100 SM

NISBAU [NOMAS]

EQUIPMENT

Contact us

Social Media